Design & Engineering Services

Designing components for handling, storing and processing corrosive or abrasive liquids and gases at normal and high temperature is a skill and should be carried out by thermoplastic and composite specialists. At Silotank our engineers must consider a number of factors in the design of products.

Chemical Barrier – a unique non-structural element of any composite product and incorporates either a thermoplastic liner or resin laminate chemical barrier. The choice of inliner or resin laminate chemical barrier is important to ensure longterm corrosion protection for the product. Our engineers select the correct inliners, resin & catalyst formulation, fibreglass reinforcement and synthetic tissue and veil materials for the corrosion barrier. The structural laminate design is aided by the use of our ‘Laminate Theory & Netting Programme’ which allows the mechanical properties of the laminate to to be simulated prior to construction. The programme allows the order of laminate construction sequence to be tested to ensure the maximum mechanical strength is achieved. Constructed laminates sections and coupens are tested independly to validate the material properties and finish product properties.

Silotank engineers individually analyse each new project and review the client and project performance specifications in order to select the right materials and construction methods. Our recommendations are not biased by limitations in our manufacturing and material processing abilities being able to offer straight thermoplastic, dual laminate construction and straight GRP constructions. We have a wide range or materials available always allowing us to make the correct recommendation.

Our experienced team of engineers and technical support specialists assist customers in the early planning and design stages.

Our 25 years of product experience ensure that our recommendation on product life cycle are accurate which allows the whole life cost of a product to be calculated to a high degree of accuracy.

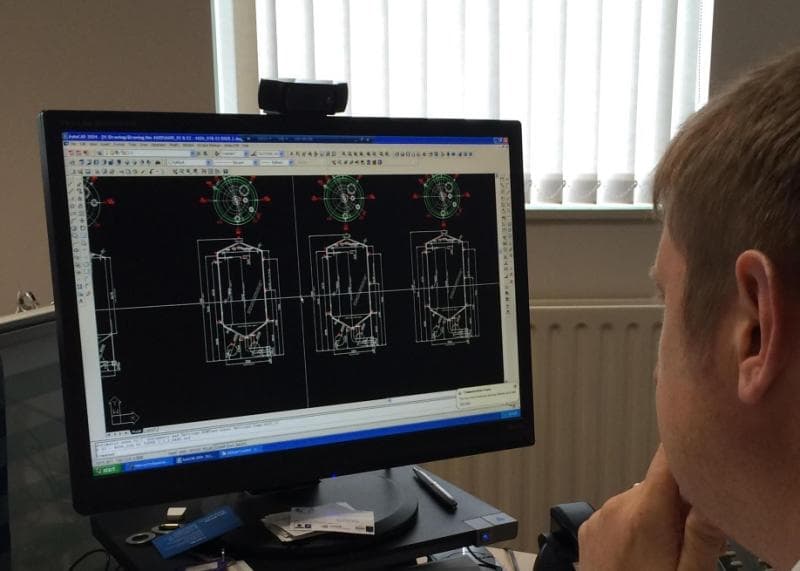

From concept to commissioning, Silotank’s team of Engineers provides the following services:

- Needs Analysis & Front End Engineering Design (FEED)

- Material Analysis and Corrosion Resistance

- Asset & Industry Standard Compliance

- Structural Calculations

- AutoCAD & Solidworks 3D Modeling

- COSMOS finite element analysis

- Process Guarantees

- CAPEX & Whole Life Cost Analysis

- Solutions to the client.

To help our clients, CPD Engineering Seminars can be arranged locally and online. Please contact for further information.